Real-time fusion is also marginally less accurate and puts a real strain on your graphics card. Most importantly, the entire scan has to be completed in a single session you cannot merge multiple scans and it’s often difficult - sometimes impossible - to scan an entire object in one go.

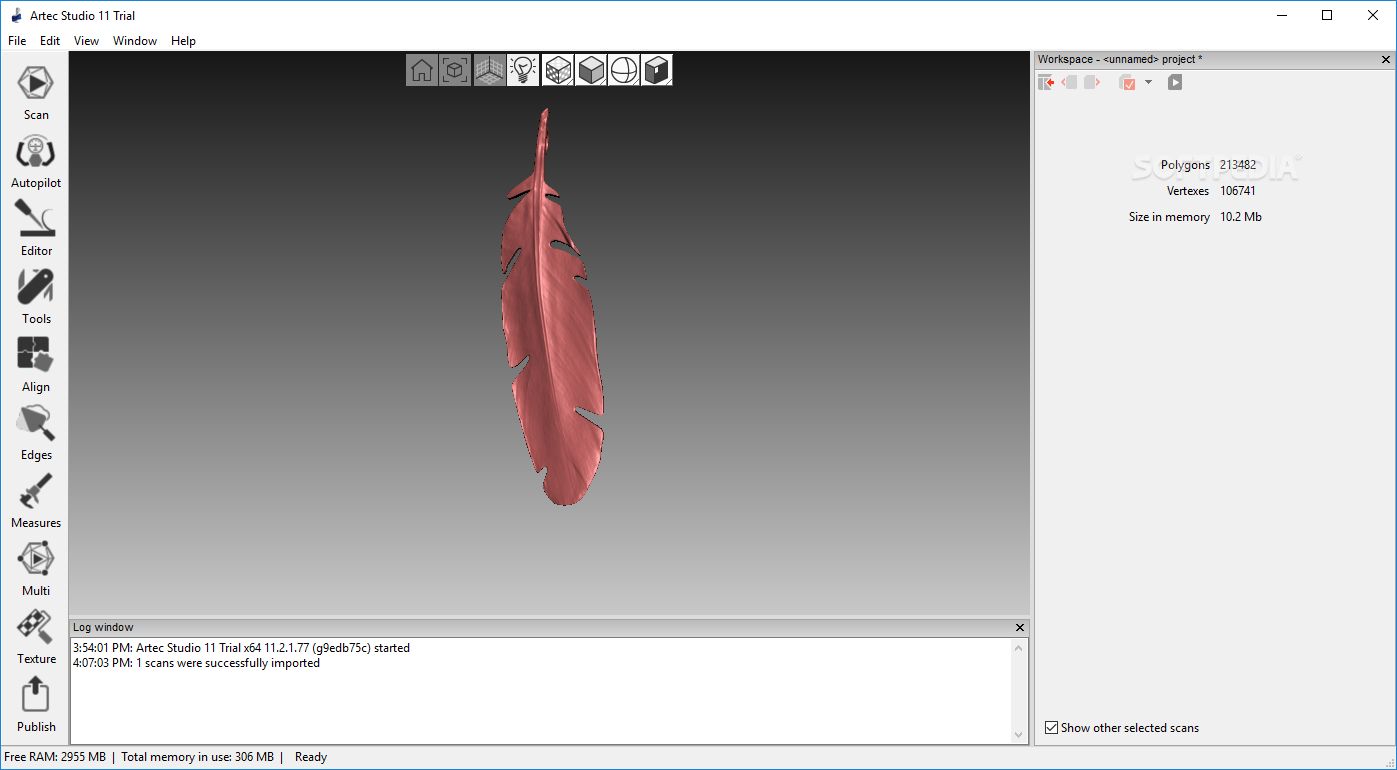

#Artec sdk vs artec studio registration

It’s the fastest and easiest way to scan, allowing you to skip the registration and fusion steps. As soon as you stop scanning, you’ve got a fused object. In this mode, the application continually stitches 3D frames together as you scan. You can actually align frames all in one go, using Artec Studio’s real-time fusion. All allow you to fine-tune the resolution. You can create a smooth fusion - good for relatively smooth objects (such as faces) - a sharp fusion - better for objects with planes angles and edges - or a fast fusion if you’re in a hurry. When everything is lined up, it’s time to weld all of the frames together into what Artec calls a fusion - a single object built from the dozens or hundreds of individual frames. You can browse through these individual frames and manually eliminate bad ones (Artec Studio gives each frame a quality score).

Artec Studio’s registration algorithms align the frames within a scan and between multiple scans. I usually manually moved and rotated things until they were fairly close and then let Artec Studio’s automated tools take over.Ī scan doesn’t immediately result in a single 3D object rather, the scanning process produces multiple different snapshots - called frames - that contain bits and pieces of the whole. It can be a bit of a challenge to align disparate scans until you get the hang of it. Next, if you took multiple scans, you will need to align them. Two separate scans of an object, before registration, alignment, fusion and texturing. Below, Artec has a video using this technique to scan a fish. You can even hang the object from a cord of some sort. You can also take multiple scans from different angles (scan, rotate the object, scan again.) If you don’t need data from some angles - maybe you’re scanning a bust of Lincoln and you don’t really care what the bottom looks like - you can easily fill in the hole later in Artec Studio. I set up a small table with a turntable on it, which allowed me to turn the object to be scanned and - in theory - keep the scanner itself in more or less the same place, moving the object rather than moving around it. My office space, while fine for writing articles, is a bit cramped for 3D scanning. If that’s not long enough, or you prefer not to risk tripping over cables while scanning, Artec offers a battery pack designed to work with their scanners and maximize mobility. The scanners plug into two cords - an AC power cord and a USB data cable. My first scan had some major problems as I climbed the 3D scanning learning curve. That wasn’t an option for me my laptop isn’t up to the task, so it was a workstation or nothing. The ultimate solution would probably be to place your object at a comfortable height in the middle of an empty room, plug the scanner into a powerful laptop, and just walk around in circles, scanning as you go.

It doesn’t hurt if you can see the scanned object as well. In fact, it is essential that you be able to see the computer screen while you scan there’s no other way of being exactly sure what is and isn’t getting scanned and to keep track of the distance to your object - something both scanners are very picky about.

Fortunately, you can see the scan happening onscreen in Artec Studio. Watch the ScreenĪs you scan, you’ll want to keep as much of the object’s surface as possible within the scanner’s field of view. You can also turn the lights off if they are distracting and rely on ambient lighting. Scan from different angles as you go, and remember to direct the cameras at those hard-to-reach spots under overhangs or in recessed areas.īoth the Eva and the Spider have built-in illumination to ensure sufficient, even lighting on your textures. The scanning process is quite a bit like spray painting: You move your hand up and down, back and forth, rotating your wrist a bit and trying to get complete coverage.

#Artec sdk vs artec studio software

When it’s time to restart, you’ll need to return the scanner close enough to a previous position so that the software can find its place again. You can pause at any time by pushing the scan button again. You point the scanner at your desired object, press a button on the handle and scan. T he Artec Eva and Spider are handheld 3D scanners around the size and shape of an old-fashioned home iron. The Eva (left) and Spider (right) scanners from Artec.

0 kommentar(er)

0 kommentar(er)